Treatment Solutions for Processing Spent Caustics

MERICON™ I, II, III and Caustic Neutralization | Treatment Solutions

Developed by Merichem Technologies, MERICON™ I, II, III and Neutralization systems are on-site treatment technologies used in the processing of spent caustics for BOD/COD reduction, odor control and/or pH adjustment.

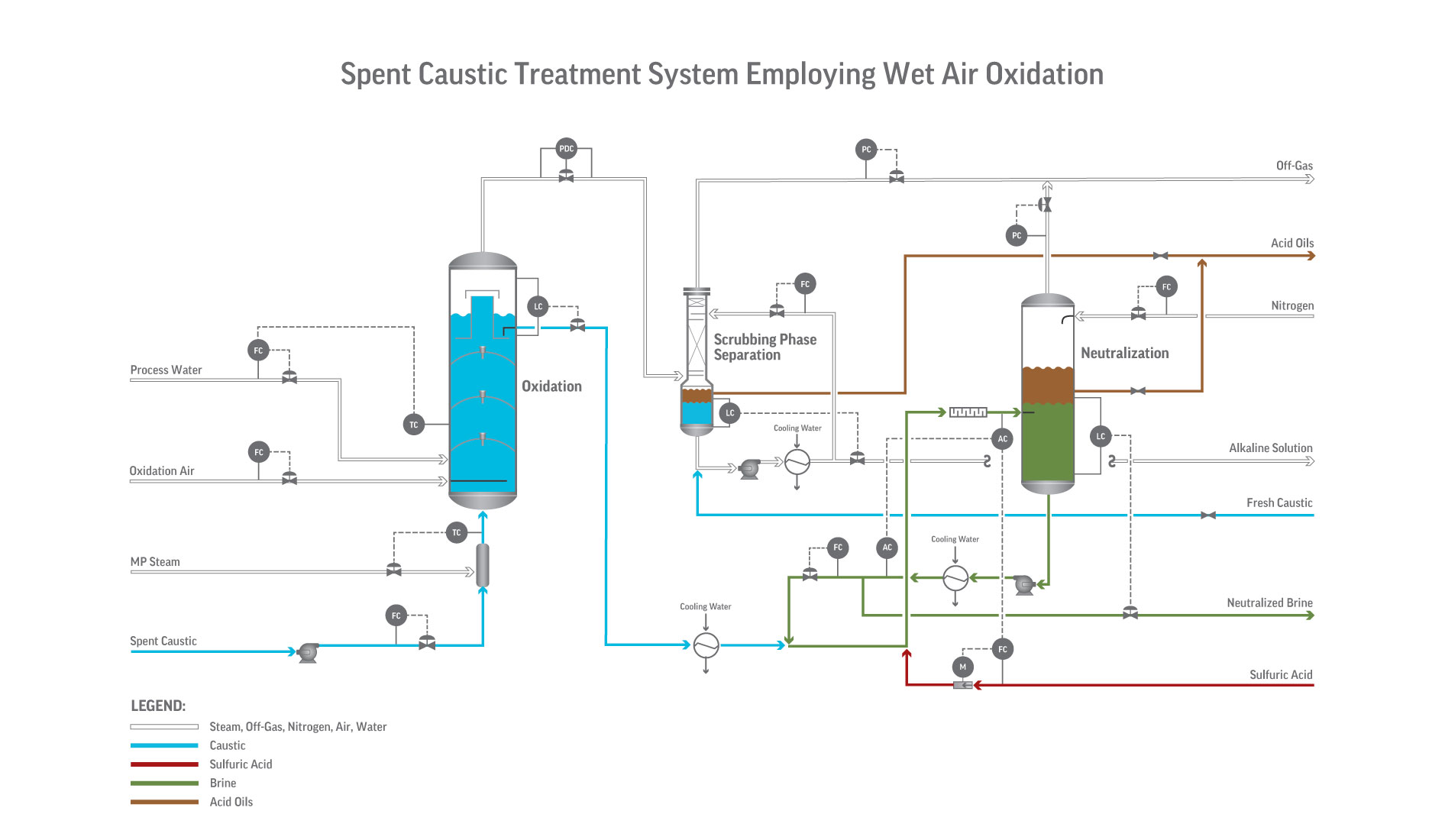

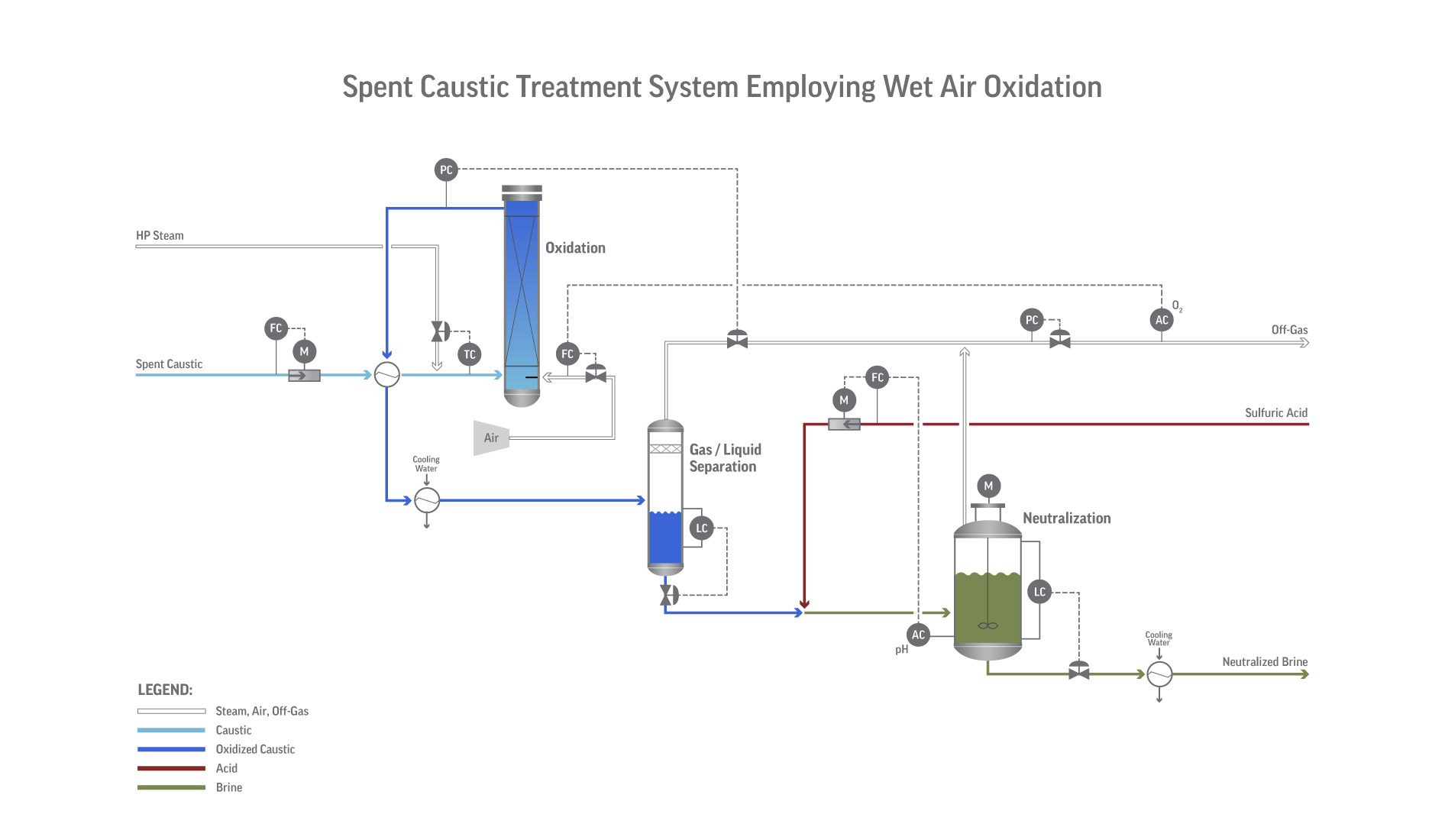

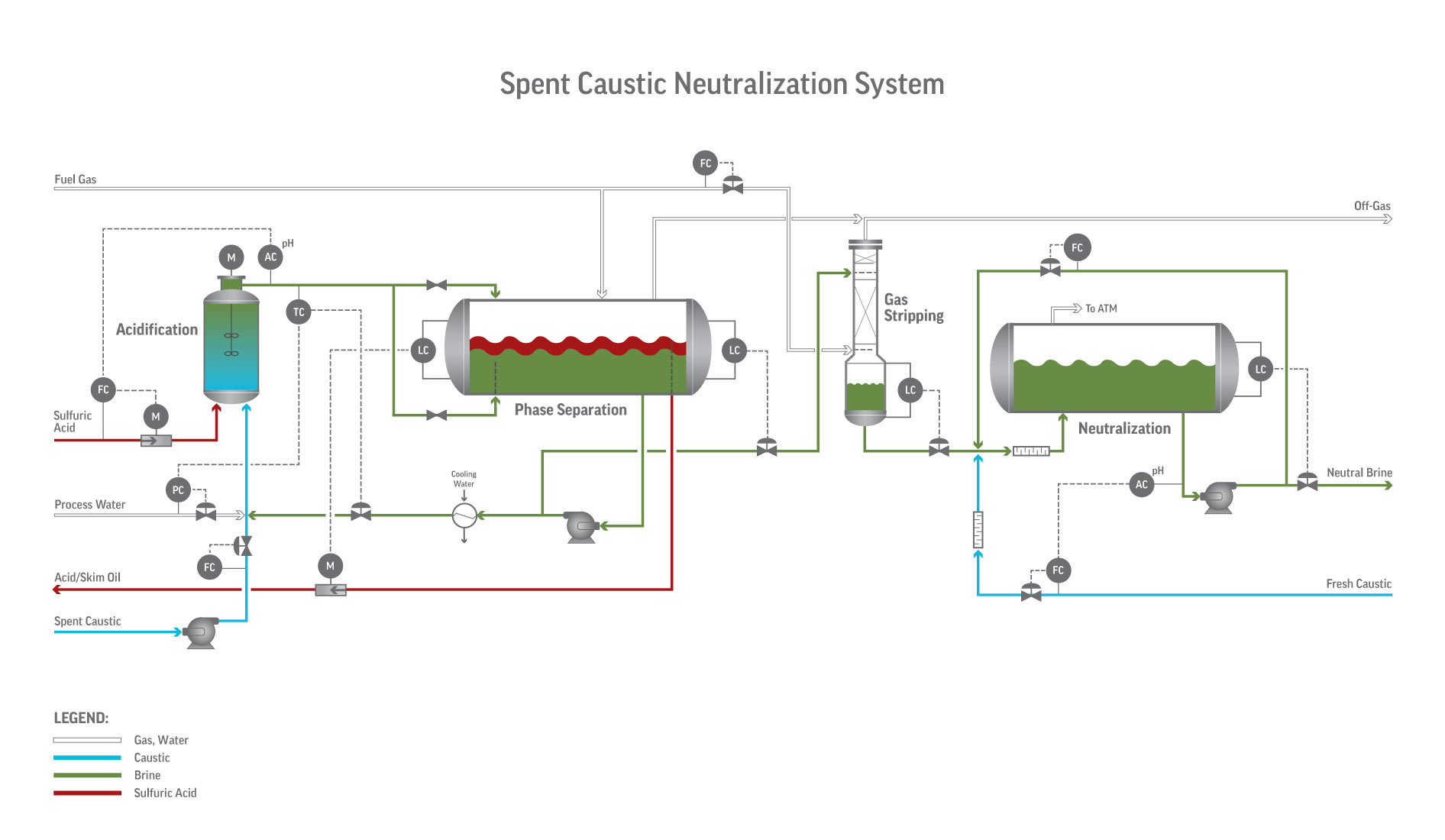

These solutions employ either wet air oxidation (WAO) or acidification—along with the option of final neutralization—to yield a treated brine effluent stream acceptable for disposal to wastewater treating facilities, evaporation ponds or waterways.

MERICON™ I Advantages

- Best for sulfidic spent caustics treatment with less demanding COD specs

- Oxidizes sulfides to sulfate and thiosulfate; oxidizes mercaptides to disulfide oils

- Built from stainless steel, reducing capital expenses

Low Pressure Variant

- Operates at 5 barg @ 100°C

- Reduces sulfidic chemical oxygen demand (COD) by 75%

- Uses plant air—no dedicated air compressors required—reducing operating expenses

Medium Pressure Variant

- Operates at 20 barg @ 150°C

- Higher performance. Reduces sulfidic COD by 90-95% along with some organic COD destruction

- Requires dedicated air compressors

MERICON™ II Advantages

- Effective in treating all mixed refinery and ethylene caustics, including naphthenic and phenolic caustics, to low COD specifications

- Oxidizes spent caustics at high pressures (30-100 barg) and temperatures (200° – 300° C) to reduce COD by 98+%

- Oxidizes all sulfides and thiosulfates to sulfates; destroys phenolics, naphthenics and mercaptides depending on oxidation temperature

- Non-catalyst process

- Minimum contaminates in the final brine

MERICON™ III Advantages

- Lower cost alternative to WAO for treating sulfidic and naphthenic spent caustics

- Acidifies spent caustics at low pressures and temperatures, releasing most high COD impurities from caustic; reduces COD by 90-95%

- Allows recapture of organic compounds (naphthenates and phenolics) if advantageous

- Flexible operation managing varying compositions and quantities of spent caustic in a timely and responsible manner

- Proven technology for removal of sulfides, mercaptides and naphthenates from caustic streams

MERICON™ Neutralization Advantages

- Neutralizes spent caustic via acid addition to yield effluents with an adjustable pH

- Lowest cost option for treating spent caustics. Consists of a single vessel

- Best for treating regenerated caustics from REGEN® systems

- Can be added to any MERICON application or sold as a stand-alone solution where pH adjustment is the only requirement

- Operates at low pressure and temperature

- Variants of this design can rival the performance of MERICON III at a lower cost by removing sulfides, mercaptides and naphthenic acids via acidification followed by stripping using fuel gas or nitrogen and reneutralization – all in a single vessel design

History of Innovation

For over 50 years, Merichem Technologies has provided proven spent caustic processing technologies to industry leaders. Our reputation for innovation, expertise and dedication to customer service continues to be unsurpassed.

Extensive Capabilities

To every challenge, we bring a comprehensive suite of capabilities to help our customers address their treatment issues. Whether it’s licensing technology, guidance, design, engineering, fabrication, testing or implementation, Merichem Technologies can apply the right resources, when and where they’re needed.